Tim Newson

Contact

Research Director

Geotechnical Research Centre

Department of Civil and Environmental Engineering

Spencer Engineering Building

Room SEB 3084

Western University

Tel: 519-850-2973

Fax: 519-661-3942

tnewson@eng.uwo.ca

Research

Dr. Newson joined the Geotechnical Research Centre in 2005 after seven years as a Professor at the University of Dundee in Scotland. He has worked in the UK, Hong Kong and Australia on engineering projects for the offshore, mining, environmental and civil engineering industries. His research interests and consulting activities include in-situ testing, constitutive modelling of clays, disposal of mine wastes, centrifuge and laboratory testing techniques, dynamic soil-structure interaction, contaminant movement through soils, offshore engineering and soils, fracture behaviour in clayey soils, dynamic compaction of soils and the biomechanics of the eye.

Featured Research Interests

Ocular Biomechanics

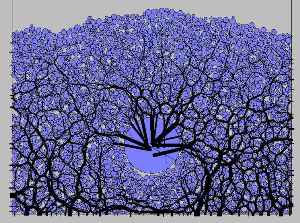

Filament element of the human cornea

The cornea and sclera are ocular tunics composed of highly ordered collagen fibrils that protect the delicate contents of the eye. In addition, the cornea also provides two thirds of the optical power of the eye. A range of problems associated with ocular performance have origins related to the biomechanical behaviour of the tissues and structures involved. Many of these can be addressed using a combination of laboratory testing, constitutive (stress-strain) modelling and computer based finite element modelling.

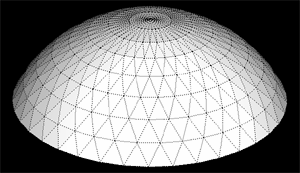

Scaled Physical Modelling in the Centrifuge

Scale model of buried culvert structure

Centrifuges may be used to model geotechnical systems due to the dominance of self-weight stresses in this problem type. The strength and stiffness behaviour of soil can be highly non-linear and stress level dependent, and to accurately simulate a full-scale structure at small scale the in-situ stresses must be reproduced in the model. This may be achieved by placing the model in an elevated gravity field - produced by the rotation of the centrifuge; an Nth scale model being accelerated by N times the acceleration due to gravity.

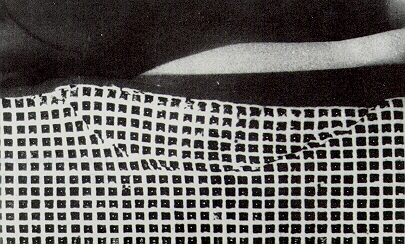

Clay foundation failure under embankment

Centrifuge modelling laws also enable processes that might prove impractical or too expensive to monitor at full scale to be investigated. Dr Newson was the Director of The Dundee Geotechnical Centrifuge Research Centre from 1999 to 2004. The machine at Dundee is an Actidyn C67-2 geotechnical centrifuge, with a 6.5m diameter fixed beam equipped with a swinging platform that can supporting a payload of 1.5 tonnes and dimensions of 1x0.8x0.8m. The speed range of the machine is 38 - 208 rpm, which gives the facility a performance of 150g/tonne. As well as the large geotechnical centrifuges, small centrifuges have been developed for use in teaching and research.

Fundamental Soil Behaviour

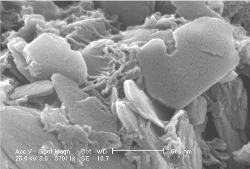

The analysis and prediction of most engineering phenomena requires a mathematical description or 'model' of the behaviour. Due to the complexity of many processes, simplified interpretations of what is occurring must be made; this entails the model only including the salient features of the behaviour. Models are usually developed by comparison withSEM image of kaolin clay with polyacrylamide 'bridges' creating metastable structure laboratory experiments and field monitoring. Dr. Newson has extensive experience of research in experimental work (computerised triaxial testing, non-standard oedometer testing, the consolidation behaviour of soft soils and the measurement of small strains) and of field testing (including site investigation).

The analysis and prediction of most engineering phenomena requires a mathematical description or 'model' of the behaviour. Due to the complexity of many processes, simplified interpretations of what is occurring must be made; this entails the model only including the salient features of the behaviour. Models are usually developed by comparison withSEM image of kaolin clay with polyacrylamide 'bridges' creating metastable structure laboratory experiments and field monitoring. Dr. Newson has extensive experience of research in experimental work (computerised triaxial testing, non-standard oedometer testing, the consolidation behaviour of soft soils and the measurement of small strains) and of field testing (including site investigation).

He also has experience of analytical and numerical model development, such as finite element modelling and discrete element modelling. Some of this work has led to the development of the CARMEL constitutive model that predicts the stress-strain behaviour of soft clays. Novel in situ material site investigation techniques are also being studied, which links to this area, as the determination of key soil parameters is best done when it is still in the ground.

He also has experience of analytical and numerical model development, such as finite element modelling and discrete element modelling. Some of this work has led to the development of the CARMEL constitutive model that predicts the stress-strain behaviour of soft clays. Novel in situ material site investigation techniques are also being studied, which links to this area, as the determination of key soil parameters is best done when it is still in the ground.

Offshore Soils and Structures

Offshore geotechnical engineering provides unique design challenges for engineers involved in securing and transporting large quantities of hydrocarbons from production fields offshore. Wind and wave loading lead to complex stress states and many potential failure modes for offshore structures and facilities. Ground investigation and laboratory testing also require experience and non-standard approaches since the 'site' can be hundreds of metres below the surface of the sea. Increasing utilisation of deep water fields have given rise to new international standards and more restrictive specifications for structures, leading to more rigorous designs and novel engineering techniques. Offshore structures can sometimes pass through areas affected by highly variable soils and hydrogeological hazards, such as landslides or gas pockets, which also add to the complexity of offshore geotechnical design.

Offshore geotechnical engineering provides unique design challenges for engineers involved in securing and transporting large quantities of hydrocarbons from production fields offshore. Wind and wave loading lead to complex stress states and many potential failure modes for offshore structures and facilities. Ground investigation and laboratory testing also require experience and non-standard approaches since the 'site' can be hundreds of metres below the surface of the sea. Increasing utilisation of deep water fields have given rise to new international standards and more restrictive specifications for structures, leading to more rigorous designs and novel engineering techniques. Offshore structures can sometimes pass through areas affected by highly variable soils and hydrogeological hazards, such as landslides or gas pockets, which also add to the complexity of offshore geotechnical design.

Application of fracture mechanics to soils

Crack development is predominant in soil structure formation. A number of fracture mechanics models have been applied to soil to describe cracking, but most are not applicable for soil in a wet, plastic state. We address this weakness by applying a new elastic–plastic fracture mechanics approach to describe crack formation in plastic soil. Samples are fractured using a deep-notch (modified four-point) bend test, with data on load transmission, sample bending, crack growth, and crack-mouth opening collected to assess the crack-tip opening angle (CTOA). [Read More]

Other Research Interests

- Contaminant flow through porous media

- Mine waste disposal management

- Unsaturated soil mechanics

- In situ testing of soil properties

- Behaviour of buried structures