Media

Contact

Communications Specialist

Faculty of Engineering

Spencer Engineering Building

Room 2072

Western University

Tel: 519-661-2111 ext. 87015

Email: engineeringcomms@uwo.ca

Western Engineering unveils the Dr. John S. Sheasby Corrosion & Wear Laboratory, with microscopic metallurgy advancements

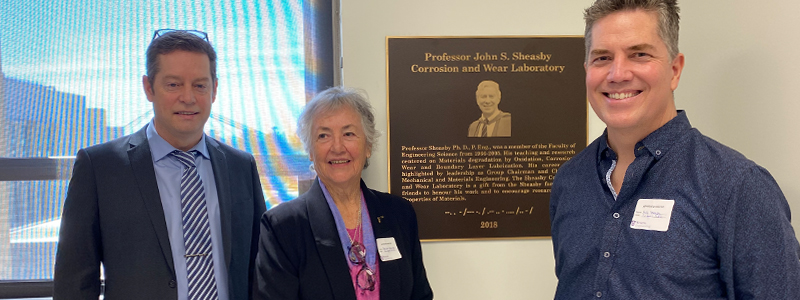

(L-R) Anthony Straatman, professor and chair for the Department of Mechanical and Materials Engineering with Marjorie Sheasby and her son, Michael.

Western Engineering unveiled the Dr. John S. Sheasby Corrosion and Wear Laboratory in the Spencer Engineering Building on April 20 in honour of the late Professor John Seymour Sheasby who served the department of Mechanical and Materials Engineering at Western from 1966 to 2005.

The laboratory is a result of a generous donation by the Sheasby family. Additional donations from friends of the family and the wider Western Engineering community allowed the faculty to equip the state-of-the-art laboratory in recognition of his accomplishments and to encourage research in the properties of materials.

The opening ceremony was hosted by Professor Anthony Straatman, Chair of the Department of Mechanical & Materials Engineering and was attended by family, friends, faculty, staff, and members of the wider Western Engineering community. Sheasby’s daughter, Susan, attended online.

“I would like to thank the Sheasby family and other donors for their tremendous support,” said Straatman. “The laboratory features specialized equipment that will enable undergraduate students, graduate students, and researchers in the department to conduct laboratory experiments and prepare samples for microscopy and scanning electron microscope imaging,” he said.

The laboratory guides the selection of the best possible materials for applications and helps identify improvements while informing research into industries and products we use every day. The new equipment will provide more reliable assessments, evaluations, and analyses for stress, erosion, and wear for use in research.

During the ceremony, Saiedeh Marashi, a Graduate PhD student and Bradley Wright, a third-year undergraduate student demonstrated their research and showed how the laboratory enriched their student experience, helping to bring theory into practice.

As part of his thesis project, Wright highlighted research into the deformation of steel using micro-indentations a third the size of a human hair. “The lab is critical to executing student research and projects that would not have been possible without the equipment,“ noted Wright. This sentiment was echoed by Marashi who said it “allowed the preparation of samples efficiently, quickly and accurately.”

Sheasby was at heart, a teacher and a bench scientist, passionate about mentorship and leading by example. His teaching and research centred on materials degradation by oxidation corrosion, wear, and boundary layer lubrication. His career was highlighted by leadership as a group chairman and chair of the Department of Mechanical and Materials Engineering. As an active researcher and scientist, he taught both undergraduate and graduate students, maintained his own research, and published in refereed journals and conference proceedings, all while carrying out his own private consulting.

Sheasby’s wife, Marjorie said, “John knew that the meticulous preparation of samples is key to the understanding of the way materials behave and misbehave. The family is pleased that the Sheasby lab honours this belief and promotes essential materials research.”

In his closing remarks, Sheasby’s son, Michael added: “The problems of today, such as the environmental challenges we face, are immediate and the work of engineers is needed to revolutionize energy capture, medical devices, transportation, and automation of services in the face of aging populations. There is an urgency. The growth of the storage of human knowledge and the tackling of great problems takes place in university halls, classrooms, and labs exactly like this…we hope [the lab] will ensure a continuation of these great projects”. He gladly noted efforts on the lab are synonymous with an expression professor Sheasby used to say, “Get on with it!”