Media

Contact

Communications Specialist

Faculty of Engineering

Spencer Engineering Building

Room 2072

Western University

Tel: 519-661-2111 ext. 87015

Email: engineeringcomms@uwo.ca

Undergraduates engineer ‘smart implant’ for hip replacement patients

Western Engineering News | March 18, 2015

By Jason Teakle

A group of four Western undergraduates are on the forefront of the latest technology to detect issues that hip replacement patients can experience with loosening caused by bone weakening – long before the best current equipment in hospitals can discover it.

Jolien Van Gaalen, a second-year Mechatronics Systems Engineering student, who is part of the research project – known as hipSENSE – supervised by researcher David Holdsworth of Robarts Research Institute, said the “smart implant” device they have developed gathers medical information and distributes data via a secure cloud to patients’ doctors.

“We hear a lot about wearable devices and there is a real need to have a more accessible way to diagnose hip implant loosening,” Van Gaalen explained. “Right now, it is really expensive for hospitals to purchase the equipment needed to perform these specialized x-rays. This device provides a more accessible method because patients don’t need to even set foot in the hospital to benefit from it.”

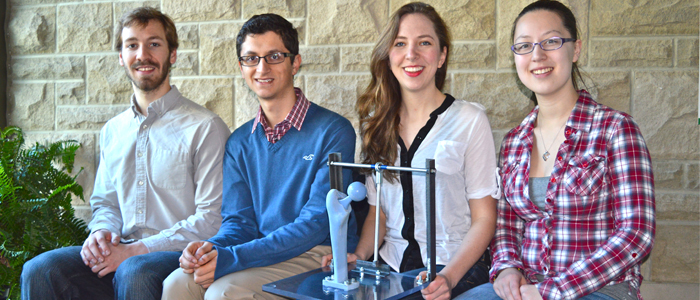

Van Gaalen is working with third-year Ivey Business School and Mechatronics Systems Engineering student Mofeed Sawan, third-year Music and Mechatronics Systems Engineering student Hilary Luo, and third-year Mechanical Engineering student Peter Nielsen. The group won first-place for the project at the Western Engineering Competition (WEC) and third-place at the Ontario Engineering Competition (OEC).

“There are currently endless opportunities to improve on how we interact with healthcare systems, and it’s becoming increasingly more important with the ageing of the baby boomer population,” Sawan said. “Our device is the world’s first smart implant that shows tremendous potential in detecting micro-loosening, and we are currently in the process of patenting our design.”

Hip implant loosening is a problem that can progress over time without patients noticing an issue, said Van Gaalen.

“Hip implants can loosen without any symptoms, which makes it difficult to diagnose,” Van Gaalen said. “If it progresses too long, pain often appears but not early on.”

The device, which Van Gaalen said is about 15 years away from actually being used on patients, will be leading-edge medical equipment containing 3D-printed metallic parts, when it makes its way into the healthcare system.

“Right now, our major focus is to 3D print the implant device using metal as opposed to the plastic we used in our design, because plastic is not strong enough to use,” Van Gaalen explained.

“The first step is to get it in the research and development market because patients would really benefit from it.”

Each year in North America, approximately 400,000 hip replacement surgeries are conducted. Out of these – about 10 per cent – are secondary surgeries to correct implant loosening.

After spending the past two summers working as a research assistant in the musculoskeletal lab at Robarts Research Institute, a pattern of implant loosening was identified – because the technology was limited.

“A problem that arose was the current technological limitation in detecting implant loosening,” Sawan explained. “Simply, there was no cheap and readily-available method to detect it.

“Our group saw the potential to leverage the recent advancements in microcircuitry and sensorization to solve this problem.”

Once the hipSENSE research group members successfully develop 3D-printed metallic parts for the ‘smart implant,’ they will focus on the process required to bring the device into the healthcare system for use in hip replacement procedures.