Contact Us

Dr. HaoTian Harvey Shi

Lab Location: SEB 3052

(519) 661-2111 x84771

Email: hshi265@uwo.ca

Research

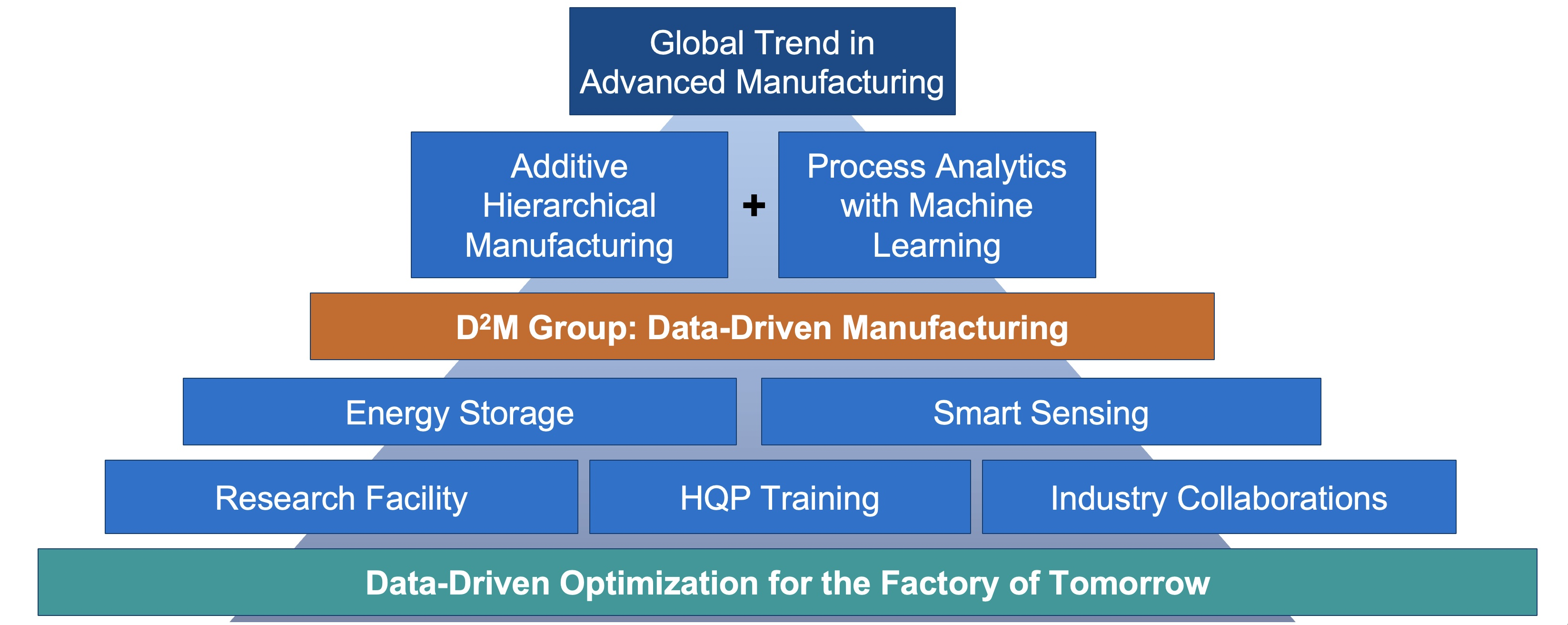

Our research group (D2M Data to Manufacturing Laboratory) is situated at the intersection between advanced manufacturing and material informatics. We are developing state-of-the-art hybridized additive manufacturing platforms to construct 3D functional materials with controlled architectures across length-scales. These 3D-printed hierarchical materials are strategically designed by tuning compositions and geometries to enhance their performance in energy storage and biomedical sensing applications. Using machine learning (ML), a tool within the artificial intelligence (AI) space, we can leverage the sizable dataset generated through automated manufacturing processes and further improve material functional performance. Hidden fundamental relations between the device performance and fabrication parameters can potentially be revealed and further predictions on product quality and performance can be made.

Energy Storage

Electrochemical capacitors (ECs) represent an emerging technology that plays a vital role as an energy supply for its high energy and power densities. Our group is utilizing the Direct Ink Writing (DIW) strategy to directly print self-standing EC electrodes that offer controlled electrical conductivity, high specific surface area, and enhanced transport properties that contribute to electrochemical performance enhancement. With many control parameters to consider during experimentation and multiple objectives for optimized outcomes in EC electrochemical testing, it is challenging to use existing modeling tools to make accurate predictions. Therefore, by using tailored ML algorithms, it becomes possible to make meaningful connections between the performance outcomes and the processing parameters, ultimately creating the next generation of optimized energy storage devices.

Electronic Skin

Electronic skin mimics the functions of actual human skin. The construction of electronic skin involves the creation of materials that combine sensing capabilities (strain, tactile, temperature, etc.) with appropriate mechanical properties (stretchability, flexibility, J-shaped behaviours, etc.). Our group works on the design of tuneable additive manufacturing strategies that can create sustainable, non-toxic, and biocompatible elastomeric/polymeric materials with desired functionalities.