Facilities

Our laboratories (TEB 417 and TEB 217) are equipped with a wide variety of instruments designed to synthesize and study the properties of the surface and bulk structure of catalysts. The designed and synthesized catalysts in our lab are tested in conventional high pressure and temperature reactors operating in batch, fixed-bed continuous flow and fluidized-bed continuous flow reactors where the energy to the reactants are provided using plasma, MW or thermal furnaces.

Our chromatographic-based instruments such as GC-MS, GC and LC with access to wide range of columns, allow us to not only qualify, but also quantify the traces quantities of chemicals.

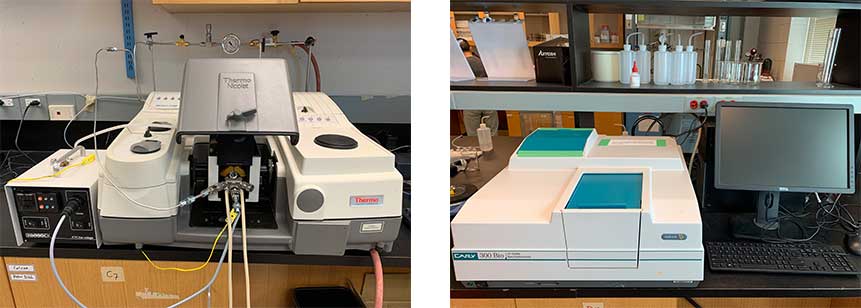

Our Opernado DRIFT IR and UV are often used to study the intermediates formed during the heterogeneous catalysis. Both of these instruments are capable of performing in situ and ex situ experiments. Two reactor cells capable of operating in conventional conditions (high temperature ~800 C, and 10 bar of pressure) and plasma mode are available in our laboratories.

Other equipment: Centrifuge, SARA and Viscometer.

Our knowledgeable research group provides consistent, accurate and comprehensive analytical services in a friendly environment and at affordable rates.

1.1 Chemical Adsorption Equipment - TPR, TPD, TPO, Pulse chemisorption

1.2 Atomic Absorption Spectrometer - Metal concentration analysis

1.3 Fourier-Transform Infrared Spectroscopy (FT-IR, Ex situ, In situ and operando) - Material characterization

1.4 Ultraviolet-Visible Spectrophotometer (UV, Ex situ, In situ and operando) - Material characterization

Operating Standard: ASTM E1184-10(2016)

2.1 GC-MS - Organic and inorganic component qualitative analysis

2.1 GC-MS - Organic and inorganic component qualitative analysis

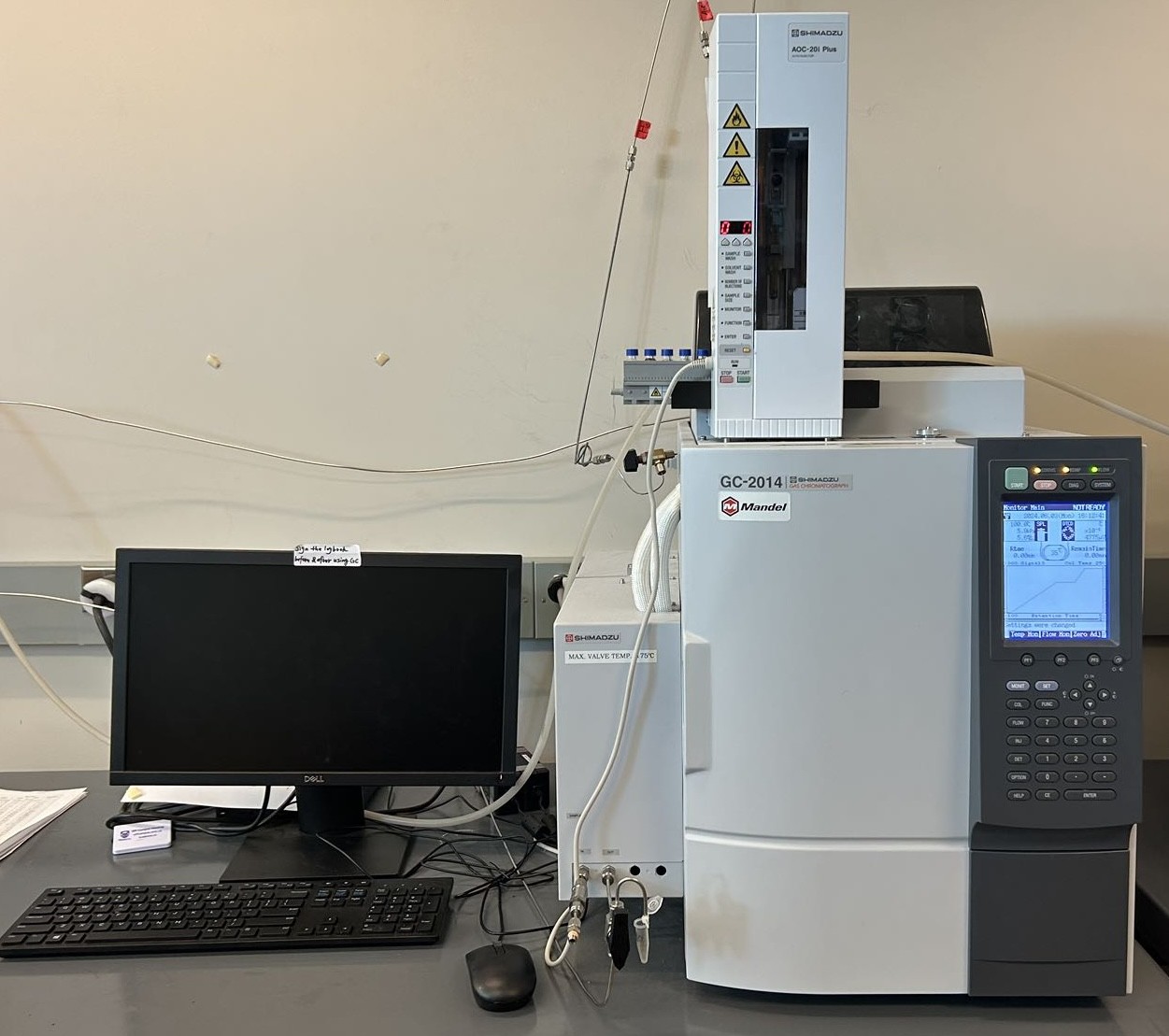

2.2 Gas Chromatograph (GC) - Organic and inorganic component quantitative analysis. Operating in both online and offline modes.

Operating Standard: ASTM E2997-16

2.3 High-Performance Liquid Chromatography (HPLC) - Organic and inorganic component qualitative analysis

Operating Standard: ASTM D7169-18

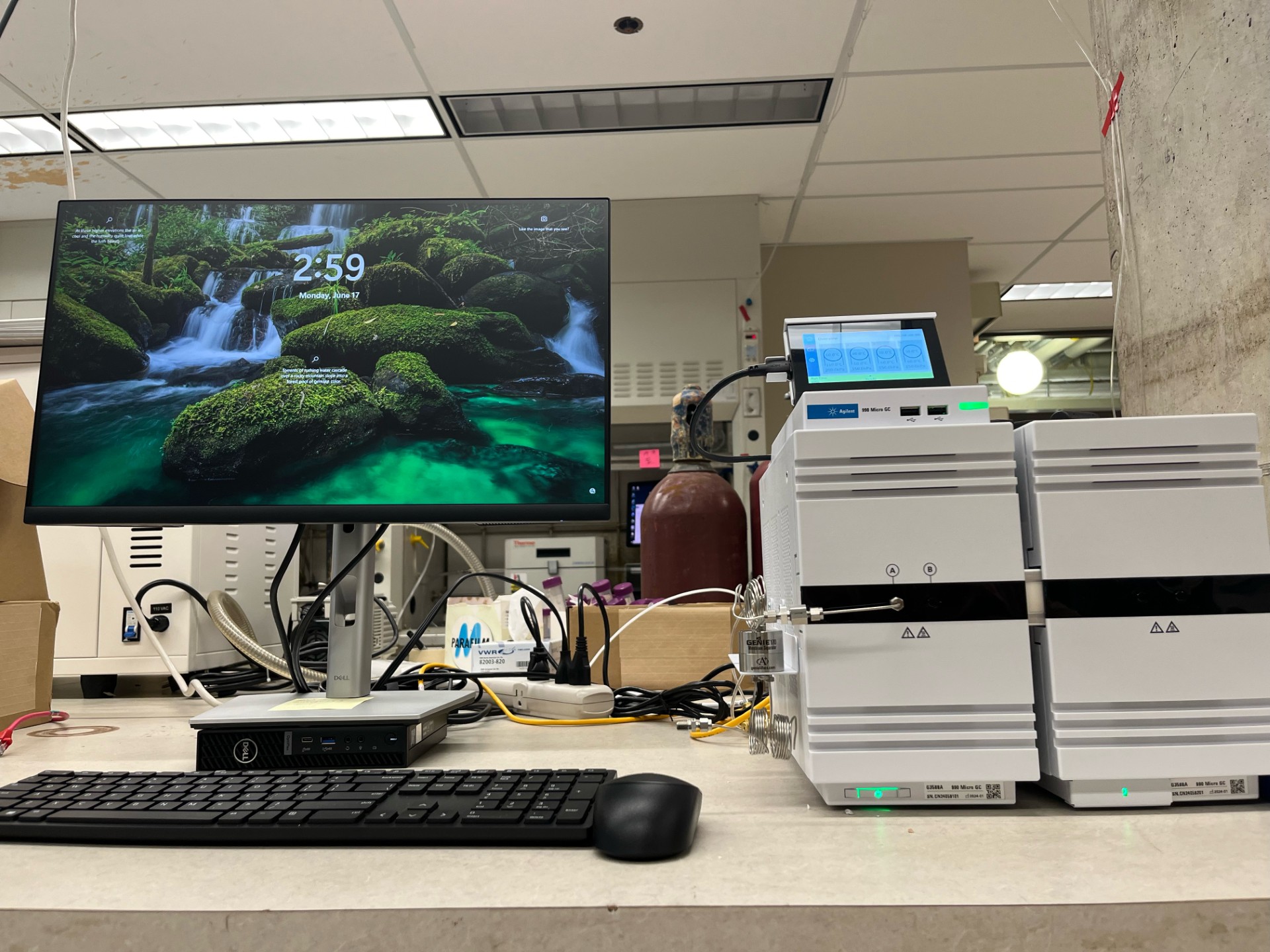

2.4 Micro Gas Chromatography (MicroGC) is a compact, rapid analysis tool for gases and volatile compounds

2.5 Adavned Gas Chromatography (GC): Organic and inorganic component quantitative analysis. Operating in both online and offline modes.

2.6 Battery station: used to safely charge, discharge, and test batteries under controlled conditions, allowing researchers to measure performance, efficiency, and stability.

2.7 Glove box: is used to handle air- or moisture-sensitive materials in a sealed, controlled atmosphere.

3.1 Autoclave Reactor System - High pressure/temperature reaction (Up to 500°C)

Examples of application: Catalytic hydrogenation reactions, selective oxidation processes.

3.2 Bench Top Reactor System - High pressure/temperature reaction (Up to 500°C)

Examples of application: Thermal cracking and catalytic cracking of oil sand bitumen, petroleum vacuum residue, biomass, etc.

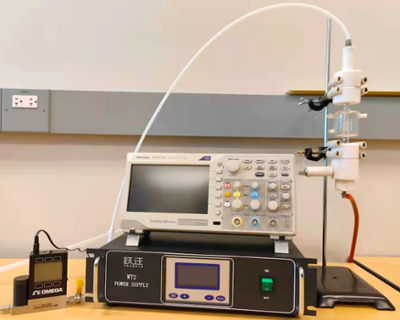

3.3 Fixed-bed Non-thermal Plasma Reactor

The plasma reaction system is mainly composed of the Dielectric Barrier Discharge (DBD) reactor, non-thermal plasma power supply, digital oscilloscope and collecting system. Its voltage regulation range is: 1-3kV, the frequency adjustment range is: 20-50kHz.

It is able to perform intense plasma catalytic reactions at room temperature, such as the CO2 hydrogenation reaction, CH4 partial oxidation, methanol reforming reaction

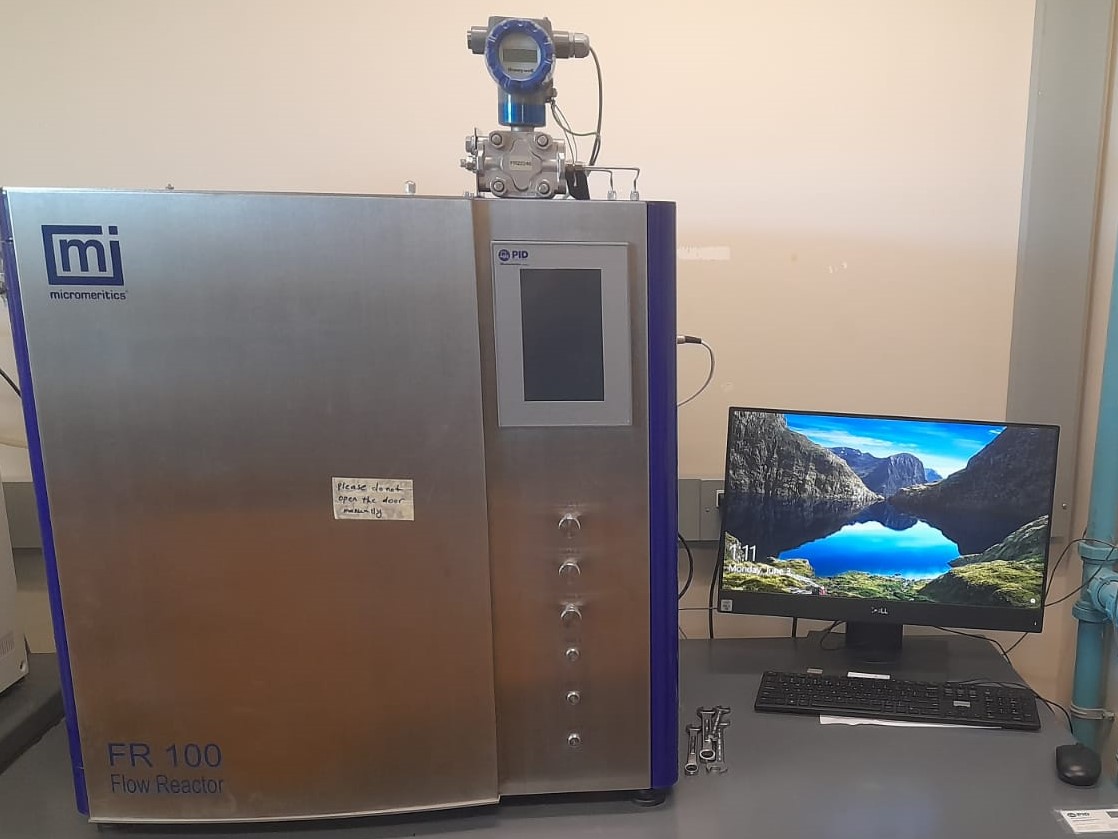

3.4. Fixed-bed Continuous Flow Reactor - Operated at high temperature and high pressure (capable of doing catalysis of supercritical fluids [SCFs])

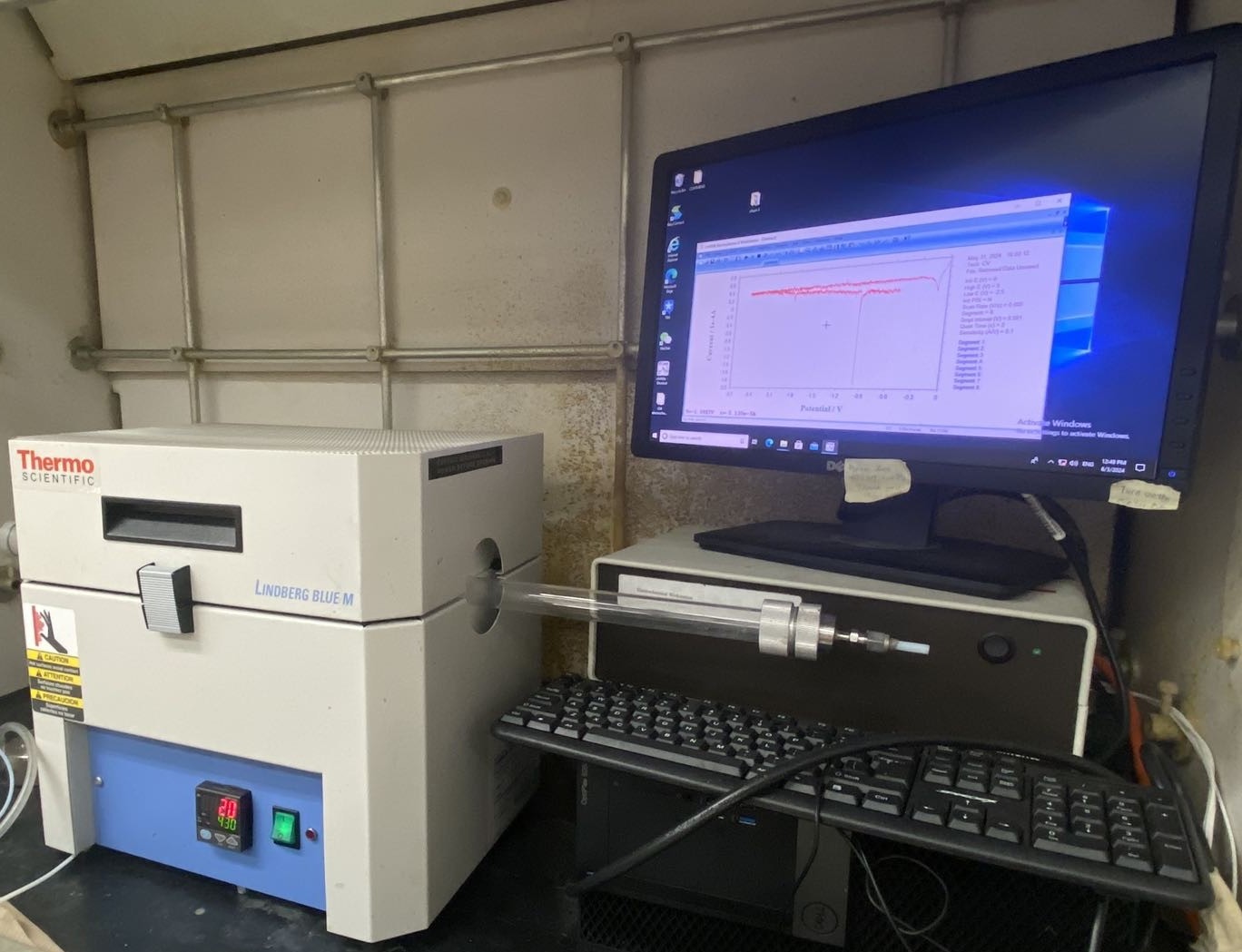

3.5 Thermal reactor (Operated at high temperature and high pressure) for CO2 conversion into valuable compounds

3.5 Electrochemical station: for studying electrochemical processes, including components to control and measure voltage and current in experiments on batteries and fuel cells.

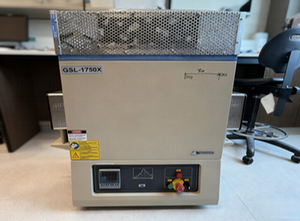

3.6 High-Temperature Tube Furnace:Used for precise thermal treatment and material synthesis under controlled atmospheres.

4.1 Conventional synthetic technqiues

4.2 Hydro-thermal

4.3 Colloidal

4.4 Ball Miller

4.5 Atomic Layer Deposition (ALD)